|

Antenna Theory and Design

LPAM antennas are more difficult to construct than their

LPFM cousins. Firstly, they have to be longer. Secondly, they

have to be vertical to work well (which becomes an issue if

the antenna is longer). Thirdly, they need to have rather long

ground radials for the same reason. I will get into why

shortly, but just keep in mind that, despite your best

efforts, practicality and the constraints of your property

will severely limit the efficiency of the antenna you can

construct. If you plan on building a Part-15 station, which

limits the antenna size to 3 meters, your efficiency will be

especially low. Efficiency for Part-15 antennas is measured in

the single digits, and sometimes even less than that.

But don't read too far into this. Practical LPAM antennas,

while seemingly awful on paper, work quite well in the real

world. Lower frequency signals propagate better than higher

frequency, which almost makes up for antenna inefficiency.

Also, there are tricks to make shortened antennas perform

better.

Antenna

Theory

First, it is important to understand that frequency can be

measured in terms of physical length. To find the length of a

given frequency, use this formula:

Where W is the wavelength ( or "wave") in feet, and kHz is the broadcasting frequency.

This is important because we can use the wavelength to get an

idea of how long the antenna should be. For example, to find

out how long a wavelength for 1600kHz would be:

or "wave") in feet, and kHz is the broadcasting frequency.

This is important because we can use the wavelength to get an

idea of how long the antenna should be. For example, to find

out how long a wavelength for 1600kHz would be:

The vast majority of antennas are not made the full size of

the wavelength, however. They are usually made in fractional

sizes of the full wavelength. A 1/4-wave antenna, for example,

would be 1/4 the length of the full wavelength. Lets say you

want to make a 1/4-wave antenna. Simply multiply the fraction

into the previous equation:

So if I wanted to make a 1/4-wave antenna for 1600kHz, I

would make it 154 feet long. Similarly, we can find the

wavelength of an antenna for a given frequency if we know its

height:

Where:

A = Antenna wavelength

H = Height of antenna

(in feet)

W = Wavelength of frequency (984,000/kHz)

The (overall) optimum height for a LPAM vertical antenna

is 1/4-wave. If you can make a 1/4-wave antenna, that's

great. But unfortunately, a 1/4-wave antenna for the AM

Broadcast Band is very long and impractical for most people.

From the above formula:

As you can see, these are very long antennas! For reasons

of practicality (and for Part-15 broadcasters legality) most

people will have to settle for much shorter

antennas.

Shortened

Vertical Antennas: An Overview

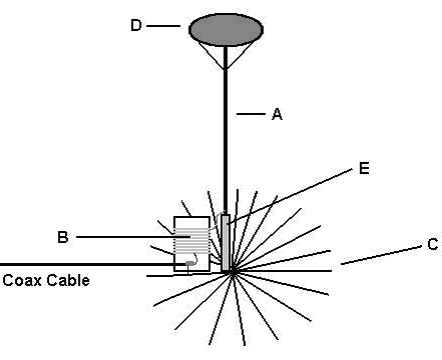

Shortened vertical antennas actually consist of five

different elements. Each is a separate component that comes

together to create the antenna.

The main components are as listed:

A) Vertical Radiator

B) Loading Coil

C) Ground

Plane

D) Capacitance Hat

E) Insulator

Vertical Radiator

The vertical radiator is the element that actually radiates

the signal. It can be a thin wire, a copper pipe, irrigation

piping, or any other sort of metal conductive material (even

an existing radio tower).

Irrigation pipe is the popular choice of commercial

broadcasters. Putting up anything that bulky, however,

requires guy wires to keep it from falling, and it can be

dangerous if it is not done right. This explains the

popularity of wire antennas or smaller elements for amateur

broadcasters. One popular material for making amateur antennas

is TV mast. Make sure to have plenty of guy wires to keep the

radiator from falling, perhaps a set of three guy wires at the

top and (if needed) another set halfway down the mast. It is

suggested that you not try to make any large-diameter antennas

too tall without having more advanced knowledge of antenna

construction.

If you do use guy wires, use non-conductive ones, such as

thick nylon wire. Using conductive guy wires can cause a lot

of problems. The diameter of the vertical has to be large (and

sturdy) enough to keep it from bending. If you are just making

a 10 foot Part-15 compliant antenna, a piece of 1/2-1 inch

diameter copper piping should suffice, and it shouldn't be

necessary to have guy wires.

If you have a long tree in the broadcast area, one idea is

to string a wire antenna up using the tree as the support. To

do this, take a trout sinker and tie it to light fishing line.

Using a slingshot, shoot the sinker over a tree or other

support until you can get it to come down through the tree

(this could take a few attempts). Once that is accomplished,

tie some nylon string to the fishing line and pull the fishing

line back towards where it was shot until the string has

replaced the fishing line. Attach a wire antenna to one end of

the string, with the other part of the wire antenna attached

to an insulator or some sort of heavy weight. Pull the other

end of the string until the wire antenna is firmly in the air,

and then tie it to a nearby tree. To maximize the performance

of your radiator, make the vertical as long as you can (up to

1/4-wave). The longer the vertical is up to that point, the

better the antenna will perform.

Loading

Coil

Impedance is a complex number, related to the resistance

and reactance in a signal. It fails simple description, but

for the purposes of this guide consider it a "type" of signal,

and that in order for your antenna to work well with the

transmitter and coax cable, it must be the same impedance. If

the output impedance of a transmitter and coax cable is

50-ohms ( ),

the antenna impedance must also be 50-ohms. A shortened

antenna exhibits a high level of capacitive reactance; in

essence, it behaves like a lossy capacitor. In order to make

the antenna 50-ohms, the excess capacitive reactance needs to

be cancelled out with its electrical opposite, inductive

reactance, which is done with a loading coil. ),

the antenna impedance must also be 50-ohms. A shortened

antenna exhibits a high level of capacitive reactance; in

essence, it behaves like a lossy capacitor. In order to make

the antenna 50-ohms, the excess capacitive reactance needs to

be cancelled out with its electrical opposite, inductive

reactance, which is done with a loading coil.

A loading coil is, in all respects, a large variable

inductor that tunes the antenna's impedance to that of the

coax and/or transmitter, which is in most cases 50-ohms.

Loading coils are designed to be variable, because for amateur

broadcasters it is impossible to determine the exact impedance

value of a homemade antenna.

Loading coils are made by taking insulated wire and

wrapping it around a coil form, such as a piece of large

diameter PVC pipe. Every 10 turns or so, there is a tap that

comes out from the coil, giving you something to attach the

transmitter signal to. You then tune the coil by selecting the

tap that provides the best match for your antenna.

This method, however, only provides a coarse tuning. In

order to get the maximum amount of power out of your antenna,

you also need to be able to fine-tune the coil to the exact

point of impedance match (called resonance). To do so, either

a variable capacitor is inserted, or a variometer is

constructed. Loading Coil design is detailed later in this

guide.

Ground Plane (Counterpoise)

The counterpoise is one of the more confusing elements of

an antenna. In a nutshell, it does two things. First, it's

what the vertical portion of the antenna "pushes" off of, an

electromagnetic behavior that is required to make the antenna

actually work. The second practical function of the

counterpoise is to provide a low-resistance return for

electromagnetic current near the antenna to make up for earth

losses.

A ground plane is a type of counterpoise that consists of

radials (wires) extending horizontally from the base of a

vertical antenna in a spokes pattern. All vertical antennas

have some sort of ground plane, as all antennas require one to

work well. You need a ground plane for your antenna to

work well. The major difference with LPAM ground planes is

that they are much longer than ones for higher frequency

antennas. From the above formulas, a 1/4-wave radial for

1600kHz is 153.75 feet long.

Note that a ground plane is not the same thing as an

electrical ground (though they are often electrically

connected to ground via the return of the coax). That is to

say, you cannot just bury a grounding rod and then use that as

your "ground plane". The behavior and purpose of a ground

plane is quite different than a simple low-resistance path to

earth, though the use of the word "ground" for both elements

often makes them sound like they are related. They are not.

If you place the radials on (or bury them in) the ground,

you will have to use a lot of radials to make up for earth

losses. Commercial broadcasters use as many as 120 1/4-wave

radials for their stations, which is considered the optimal

configuration. But this is a potentially time consuming and

expensive task (at 1600kHz, you would need 18,450 feet of wire

to do this!) Like with the vertical radiator it is often

impractical to achieve an optimal ground plane, but try to

make it as good as you can. A lousy ground plane will work far

better than no ground plane at all.

One way to reduce earth loss is to place the antenna on top

of an elevated roof. If the roof happens to be metal, attach

the electrical ground to it and the roof itself will serve as

the ground plane. If the roof is not metal, placing an antenna

on it will still most likely improve range. Another benefit is

that considerably fewer radials will be needed. Elevated

antennas only typically need 4-8 radials to achieve optimal

efficiency, far less than are needed to reach the same level

with an earth-based antenna.

Here are some general rules for constructing an effective

ground plane:

Have all radials equally spaced in a circle around the

antenna. Attach each radial to a central location at the base

of the antenna, such as a pie pan or a circular loop of thick

copper wire. Make an electrical connection, such as an

alligator clip, or solder the radials to the centerpiece.

The radials should be as long as possible, keeping

property size in mind. Optimal length for radials varies with

the length of the vertical radiator, but generally the longer

the better. Don't use radials longer than 1/4-wave unless you

know what you are doing.

The more radials the better, but the gain becomes

progressively smaller. Increasing the number of radials from 4

to 16 significantly increases antenna efficiency, but after

that the gains become less radical. Increasing the number of

radials from 16 to 60 would provide less of a gain. If you are

using an elevated ground plane, you shouldn't need more than

4-8 radials.

More is better than longer. 8 radials of 1/8-wave are

better than 4 radials of 1/4-wave.

Insulated or bare wire can be used. Copper is preferred,

but aluminum can be used if the acid level of the soil is low.

Sizes can be anywhere from 5-20AWG. Go with what's cheapest.

The radials don't need to be in a perfectly straight line

from the antenna, nor do they have to be perfectly evenly

distributed. They can be bent, risen, or lowered slightly to

fit the property.

If it's not possible to make a radial system, there are a

few long-shot alternatives. One alternative is to bury a few

ground rods or several copper pipes near the base of the

antenna (eight feet into the ground), wire them together and

then use that as your ground. You could also attach the ground

to underground water pipes or a nearby faucet. It might be

better than no ground system at all, but don't expect

miracles.

Capacitance Hat

A capacitance hat is a component that helps to even the

current flow through an antenna. Without one, more of the

signal is propagated at the bottom of the vertical radiator

than at the top. If more of the signal is propagating at the

top of the antenna, the signal does a better job of getting

above trees and nearby objects. Capacitance hats also help to

increase the bandwidth of the vertical radiator, which can

lead to improved audio fidelity if the "Q" factor of the

antenna is too high.

A capacitance hat can be a large metal disk, a pie plate

with spokes of stiff copper wire extending from it, a pyramid

of wires extending a few feet from the top and attaching to

the guy wires, or simply anything metal coming out

horizontally from the top of the antenna such as several wires

stringed to insulators (anything non-conductive) on nearby

trees. Capacitance hat construction is not critical, feel free

to experiment with whatever works best for you.

Insulator

This is the base of the antenna. It has to be

non-conductive and sturdy enough to hold the antenna in place.

Avoid using concrete and wood to directly insulate the

antenna, because they can absorb water. Rubber and plastic

insulators work best. If you are using a wire antenna strung

from a tree, nylon string tied to something heavy on the

ground serves as a good support to tighten and hold the

antenna in place. If your vertical radiator is thicker than a

wire, the insulator will probably have to be

hammered/concreted into the ground for stability. Don't forget

the guy wires.

Building a Loading Coil

Four things are considered in the development of a loading

coil. First, they need to be able to coarsely vary in

inductance, which is implemented in the form of tap points in

the coil at certain intervals. Secondly, they must be able to

fine-tune to the exact level of inductance needed. Thirdly,

they need to be sturdy, which means the wires must be firmly

on the coil and the coil must be able to handle unfavorable

weather conditions. And finally, they need to have enough

inductance to properly tune the antenna. Variable loading

coils can take a little time to make (a day or two), but once

you build one you never have to do it again, even if you

change frequencies or the antenna.

There is no standard for what wire size to use, but it's a

good idea to use 20AWG or larger wire to avoid loss due to

wire resistance. The wire must be insulated when wrapped onto

a form. Plastic insulated, litz, and enamel-coated wires work

just fine. Enamel coated wire might look like bare copper at

first sight but it isn't, it tends to have a darker, redder

color than copper. Enamel coating can be removed with

sandpaper or burned off with a lighter. The coil form most

people use is a large (4 to 12 inch) diameter PVC pipe. PVC

piping can be purchased at most local hardware stores by the

foot; 2-3 feet should be all that is needed. Basically

anything that is round and doesn't cause significant RF loss

will work well, such as a plastic drinks container or an

oatmeal cylinder. If you do get PVC pipe, get the white kind.

The other kinds of PVC have different "dielectric" properties

and can be lossy at RF (though this is a bigger concern at

higher frequencies than it is at mediumwave).

How much inductance (how many turns of wire) should your

coil have? This depends on antenna length, antenna diameter,

and operating frequency. We can approximate the amount of

inductance required to tune an antenna, which is good enough

for designing a loading coil. Make sure you design the coil so

that it is somewhat larger than needed. If the coil is too

small, you won't be able to tune it without adding more

inductance, so good engineering practice calls for the design

of a loading coil that has more inductance than is needed for

the specific application.

Loading Coil Inductance Values

Frequency

(kHz)

|

Ant. Height (ft)

|

Diameter (in)

|

Inductance

Req. (uH)

|

1600

|

10

|

1/16

|

134

|

1600

|

30

|

1/16

|

86

|

1600

|

50

|

1/16

|

62

|

1600

|

10

|

1/2

|

119

|

1600

|

30

|

2

|

62

|

1300

|

10

|

1/16

|

204

|

1300

|

30

|

1/16

|

133

|

1300

|

50

|

1/16

|

97

|

1300

|

10

|

1/2

|

181

|

1300

|

30

|

2

|

95

|

1000

|

10

|

1/16

|

345

|

1000

|

30

|

1/16

|

256

|

1000

|

50

|

1/16

|

168

|

1000

|

10

|

1/2

|

305

|

1000

|

30

|

2

|

162

|

700

|

10

|

1/16

|

703

|

700

|

30

|

1/16

|

463

|

700

|

50

|

1/16

|

349

|

700

|

10

|

1/2

|

623

|

700

|

30

|

2

|

333

|

500

|

10

|

1/16

|

1379

|

500

|

30

|

1/16

|

910

|

500

|

50

|

1/16

|

689

|

500

|

10

|

1/2

|

1222

|

500

|

30

|

2

|

654

|

Once the required inductance is known, the following

formulas can be used to form the coil:

or

Where:

L = Inductance of coil in microhenrys (ÁH)

N =

Number of turns

D = Diameter of coil in inches (twice the

radius)

H = Length of coil in

inches

Tapping the Coil

One of the "gotchas" of loading coils is that you cannot

wrap together a large coil, sand off an up-down section of the

insulation and tap the wires as-is. It simply doesn't work,

because alligator clips cannot attach to the wire. Unless you

are designing a roller-inductor (which is usually more

difficult), you have to build taps into the coil while you are

looping the wire. The best way I have found to make taps is to

use this method:

First you drill three holes into the form every 1/2 inch or

so, moving up until the coil has several sets of holes. Then,

start wrapping the wire around the loading coil firmly, and

when you come to one of the holes, push the wire into it, and

then pull it out tightly through the center hole. Place the

wire for the next segment in the other hole and through the

center, strip off the insulation with sandpaper or a wire

stripper, and then twist and solder the two wires together.

Repeat for every hole until you have the desired maximum

inductance. The inductance can be found by applying the

inductance formula as you go along.

Another quick and dirty way that works is to simply twist

the wire at each tap point as you are wrapping the wire to the

form. After you are done, sand off the insulation from the

twisted elements and you have coil taps. This could be

difficult, because the loops might come unturned when tension

is applied to make the wire fit the form tightly. One way to

resolve this is to apply superglue or solder the twisted wire

together as with the above method. When you are looping the

wire to the form, keep applying tension to the wire, otherwise

it will loosen and the coil will deform. I have found that

applying a small amount of superglue helps to keep the wires

in place. Every tap point or so, dab some super glue near the

taps and in a few places across the looped wires. Let it dry

for a few minutes, and then continue.

Fine

Tuning Loading Coils

The coil tap method only gives a coarse tuning range. In

order to get good performance out of your antenna, you have to

be able to fine-tune to the exact point of resonance. That is,

we want to have the ability to both coarsely-tune and then

finely-tune the loading coil. The coarse tuning part (the

taps) will change the amount of inductance greatly, whereas

the fine-tuning part will allow us to change the inductance a

smaller but more precise amount. This involves either

inserting a variable capacitor between the loading coil and

ground, or making a variometer. Inserting a variable capacitor

between the coil and the ground allows for a fine tune,

because it tunes more smoothly and precisely. Variable

capacitors can only tune a small amount because of their low

capacitance values, so coarse tuning is still required. With a

variable capacitor, one sets the inductance to be slightly

higher than is required for resonance, and then the capacitor

is turned until the excess inductance is cancelled out, which

creates exact resonance.

The biggest drawback with a variable capacitor is that it

can be hard to find them (your best bet is at HAM fests and

old electronic parts stores). Also, after about 10 Watts they

have to be high voltage or else they won't work (the RF

electricity will arc across the capacitor's metal plates). If

you run into this problem or can't find a variable capacitor,

an alternative is to use a variable-inductance method of

fine-tuning, such as a variometer.

The

Pseudo-Variometer

A pseudo-variometer is basically a large outer loading

coil, with a smaller inner coil inside of it. The inner coil

can rotate, and is connected electrically in series with the

outer coil. When the inner coil is turned, it slightly changes

the overall inductance of the loading coil, allowing for a

fine-tune.

Variometers have become a rare item since the advent of

high frequency communication. In the early days of radio they

were used for tuning receivers, but were quickly phased out in

favor of the more selective variable capacitors. Despite being

out of use for years, they have seen a recent revival in

amateur broadcast antenna tuning. In my own work, I have found

that variometers work very well for tuning shortened broadcast

antennas. They can be built from scratch out of readily

available parts, and aren't prone to shortouts at high

voltages. Variometers will be slightly more lossy than

variable capacitors, but not by a large amount. Real

variometers have a large amount of inductance on the outer

coil and an equally large amount of inductance in the inner

coil. This makes their tuning range very wide, which is why

they were popular with early radio receivers. A

pseudo-variometer is very similar to a variometer, except that

the inner coil contains significantly less inductance. The

idea is to make a coarse tune with the taps on the outer coil,

and then to use the inner coil to change the inductance

slightly.

Good engineering practice would call for the inner coil to

be able to change the inductance more than the total amount of

inductance between each tap point. Because this is a fairly

complex analysis, I have opted to keep it in the Advanced

section of the LPAM Handbook. The most important thing is to

make the inner coil have more inductance than is needed.

The primary (outer) loading coil for a variometer can be

made exactly the same way that the loading coils above are

made, except that there is a space in the middle of the outer

coil for a handle to turn the inner coil with. The

construction details of the inner coil are not critical, 15-45

turns sloppily wrapped around a form 2-6" in diameter and

perhaps 4-8" long (depending on the outer coil size) will work

just fine. 40-80uH of inductance should be more than enough to

do the tuning.

Tuning the

Antenna

Once the loading coil is ready, you have to tune it to

resonance. Tuning a mediumwave antenna is different than most

other types of antennas. Because of the lower frequency, most

commercially retailed wattage/SWR meters do not work. Because

of this, a little bit of ingenuity is needed to actually know

when you have tuned the antenna.

When the loading coil is properly tuned to resonance, the

power level going to the antenna and the signal strength

coming out will be maximized. Knowing this, we can determine

the point of resonance by finding the peak rating on meters

that determine either of these things. The first way to do

this is to put an RF ammeter between the loading coil and the

antenna. This is the best method, but it requires an ammeter

that works at mediumwave frequencies.

If you don't have an RF ammeter, the next best way is to

use a field strength meter. If you don't have a field strength

meter, you can make a crude one very easily. Field strength

meter schematics are available here.

Homemade field strength meters won't give a calibrated

reading, but they are good enough for determining the

resonance point of an antenna. When using one, make sure to

keep it within a few feet of the antenna, otherwise the

transmitted signal will be too weak for the field strength

meter to see. Then, simply tune the antenna until the highest

point on the meter is reached.

Tuning the antenna is simple. First, attach the antenna

clip to the uppermost tap and attach the transmitter clip to

the lowermost.* Turn the transmitter on (if power is variable,

set to lowest power). Don't put any audio into the transmitter

while tuning. Then, while looking at the meter, take the

transmitter clip and keep moving it up, one tap at a time,

until about the middle of the coil. Whichever tap gives the

highest reading on the meter is the tap point you will use (if

there's no noticeable difference, set it to the first tap

after the ground). The point of this is to find the best

impedance match for the transmitter clip.

The next step is to tune the antenna. Take the antenna clip

and move it to the same tap as the transmitter. Slowly turn

the variometer or the variable capacitor, and if the antenna

doesn't resonate, move to the next highest tap and try again.

You will notice that when the antenna is resonating the meter

reading will go up significantly. Once the antenna is tuned

and ready, set the transmitter to full power and you're ready

to broadcast.

*The image above intends to show the electrical connection,

connecting the male end of a coax cable directly to the tap

would be impractical. Mount a female SO-239/BNC connector onto

the unused space of the loading coil, solder wires to it, run

them through a drilled hole to the outer coil, place alligator

clips on the ends, and then tap the coil that way.

Safety

Factors

Static Charge

In dry windy conditions, antennas can generate a static

charge that can damage the transmitter. It can also shock you,

which isn't dangerous, but could cause an accident if the

antenna is on top of an elevated roof and the shock causes you

to fall. Because the static charge is DC, it is relatively

easy to separate and remove it from the antenna. Infact, if

there is a connection between the vertical radiator and the

ground on the loading coil, the static charge should drain off

naturally. If not, you can install a high-inductance RF Choke

between the hot wire and ground. The RF won't pass through,

but the static charge (which is DC) will. Installing a

500k-1MEG ohm resistor between the antenna and the ground will

also bleed off the charge, but will take a small amount of

power out of the antenna.

RF Burns

An RF burn is the result of touching something carrying RF

power (such as the antenna wire). It usually just creates a

tingling sensation at the touch point, but at higher levels

(greater than 10 watts) it can create a burn, similar to if a

hot surface or coals were touched. RF power usually conducts

through the outer skin and therefore isn't typically dangerous

to humans in terms of heart failure or shock. However, this

"skin effect" is no guarantee: it is still possible to

electrocute, shock, or even kill yourself with RF power! It's

a very good idea to take precautions to avoid exposure to RF

power. If you are running higher power levels, it is advisable

to put up a fence or a warning sign so that others do not

touch the wire. When tuning the antenna, putting on rubber

gloves of the gardening or chemical type will keep you from

being burned.

Lightning

Lightning is a daunting problem for low power broadcasters.

If you live in an area that is prone to thunderstorms, some

form of lightning protection will be needed. Don't think it

can't happen to you! I have heard many stories of lightning

hitting unprotected low power broadcast antennas, and the

results are very destructive (though thankfully, I have yet to

hear of a fatality).

When lightning hits an unprotected antenna, the electricity

will enter the transmitter and destroy anything connected to

it (audio amps, computers, ect). If a DJ happened to be on the

microphone, he could also be the victim of a lightning strike.

A defensive mechanism needs to be put into place to keep

equipment and people safe in the broadcast room.

The common practice for radio broadcasters is to bury a

ground rod (or copper pipe) under the antenna, and attach to

it a thick copper wire (4AWG) with its end very close to the

bottom of the vertical radiator without physically touching

it. Lightning will spark across the small air gap to the

copper wire, and then run into the ground rod. The ground rod

must be at least 8 feet long to be effective. If you're

paranoid, there are lightning suppressors that go in series

with a 50 ohm coax cable, which also require a grounded wire.

A combination of both methods could be used.

If you are extremely paranoid or are in a high risk area,

additional steps can be taken with the transmitter. It

wouldn't be a bad idea to put the transmitter in a different

area than the broadcast room (remember that for Part-15, the

transmitter needs to be at the antenna anyways). The bottom

prong on three-prong AC outlets is electrically connected to a

ground rod in most homes. If the transmitter case is metal

make sure it is grounded, this provides another route for

lightning. Another option is to separate the physical

connection between the transmitter and the studio by using a

wireless link, such as a WiFi Internet system or a Studio to

Transmitter Link (STL).

Summary

LPAM antenna design is fairly complex, and if you're new at

this it might take a few reads through this chapter before the

concepts and procedures make sense.

|